PRODUCT FEATURES

Fast scanning speed

The single-sided scanning time is less than 3 seconds. Scanning small parts only takes a few minutes. Scanning a 1-meter-sized object takes about 20 minutes.

High precision, high fidelity

Dense point cloud data can be generated, and data capture is clearly expressed even for complex surfaces.

For black and reflective objects

Black and reflective objects do not need to be sprayed with contrast agent, and the software can select features for fully automatic stitching, eliminating the need for marking points, greatly saving operation time.

400x300/200x150/100x75

0.010~0.015/0.01~0.015/0.01

1000mm~3000mm/

300mm~1000mm/10mm~300mm

180mm-1000mm

6,300,000X2

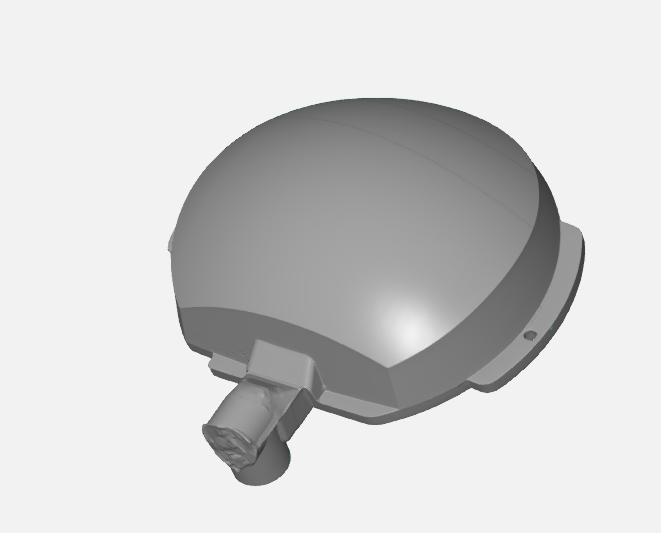

Blue light phase shift fringe grating

Fully automatic landmark stitching; feature stitching

0.6s

0.03mm

ASC ; PLY ; STL ; OBJ

Why use blue light:

The blue light scanner has a filter installed on the lens, which only allows blue light of a specific wavelength to pass through. Since the blue light content in natural light and lighting sources is very small, most of the light is filtered by the filter, but the light from the blue light projection source can be collected by the lens cup image sensor. In this way, most of the interference from ambient light is eliminated. Scanning can be performed in complex light environments in the workshop; the use of high-brightness LED cold light source greatly extends the life, generates less heat, and has high scanning accuracy and stability; the use of low-distortion lens further improves scanning accuracy.

Applications of blue light:

In some applications, it is impossible to completely block the ambient light at the scanning site. In this case, the ambient light will affect the scanning results.

1) Excessive ambient light will saturate the image sensor;

2) AC lighting source will bring AC noise to the scanning results;

3) Constantly changing ambient light will affect the scanning results.